The last few years were challenging for manufacturers everywhere, to say the least. After navigating a multitude of supply chain and labor gap issues, every manufacturing company is looking for solutions to build a more resilient business operation.

To understand these challenges and how manufacturers are overcoming them, SYSPRO partnered with Frost & Sullivan to survey small and mid-sized manufacturers worldwide.

Frost & Sullivan’s team of experienced consultants extracted over 360 data points from in-depth interviews and 290 online survey data points from executives across North America, Europe, Africa, and Asia-Pacific.

In our full report to be released in 2025, you’ll get to know:

- The latest trends shaping the industry.

- How manufacturers are leveraging technology to drive efficiency.

- Their challenges and opportunities.

- And much more…

Throughout this report, we will answer some of the most pressing questions complex manufacturers are asking to improve their operations.

- Automation, IIoT, and AI: How Emerging Technologies Are Reshaping Manufacturing

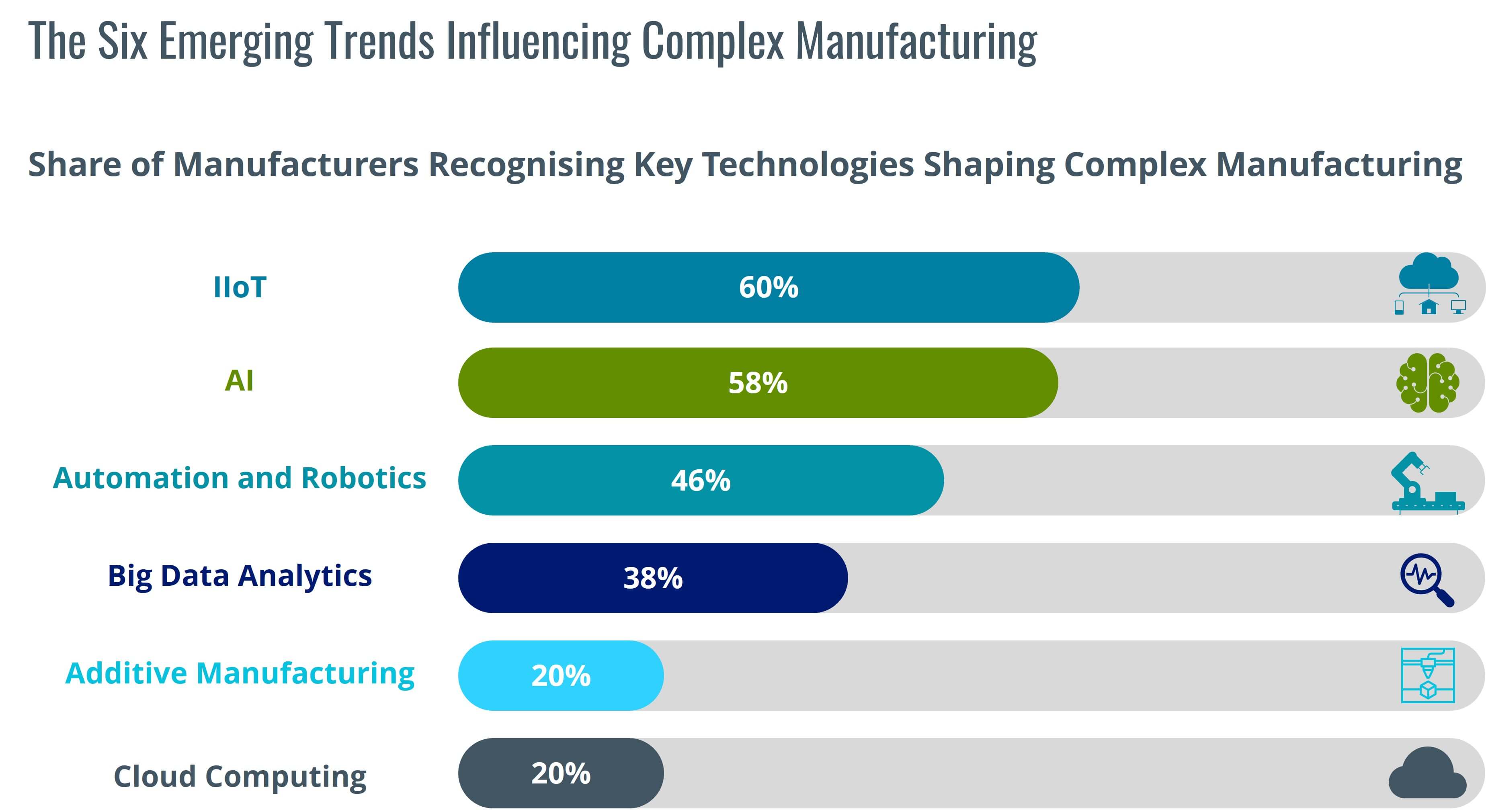

Approximately 37% of surveyed manufacturers have adopted Automation and Robotics globally, and 18% have implemented IIoT technologies to improve their manufacturing processes. Overall, we identified six emerging technologies shaping and impacting the complex manufacturing sector. Adoption rates vary across these technologies, but interest in exploring these remains high amongst all respondents.

AI, which seems to be everywhere, has a shockingly low adoption rate.

Only 19% of the respondents have adopted AI and machine learning technologies.

The full study goes beyond the adoption of emerging technologies and explores factors such as the effects of government policies and human-robot collaboration on productivity.

- Are emerging technologies boosting manufacturing efficiency?

From our survey results, it’s clear that manufacturers are exploring emerging technologies to enhance their operations.We also found that small and medium-sized manufacturers can boost productivity by 26% to 50% by adopting emerging technologies like AI, Big Data, and Robotics.

Specifically, for the USA market, this could result in significant growth as labor productivity declined in the last quarter of 2023.As more and more manufacturers gravitate towards emerging technologies in the future, smart factories will also become more mainstream. However, manufacturers are concerned about cybersecurity with 50% of the respondents noting that it’s critical amid growing technological complexities.Other than cybersecurity, our research highlights other concerns and challenges manufacturers foresee in the near future.

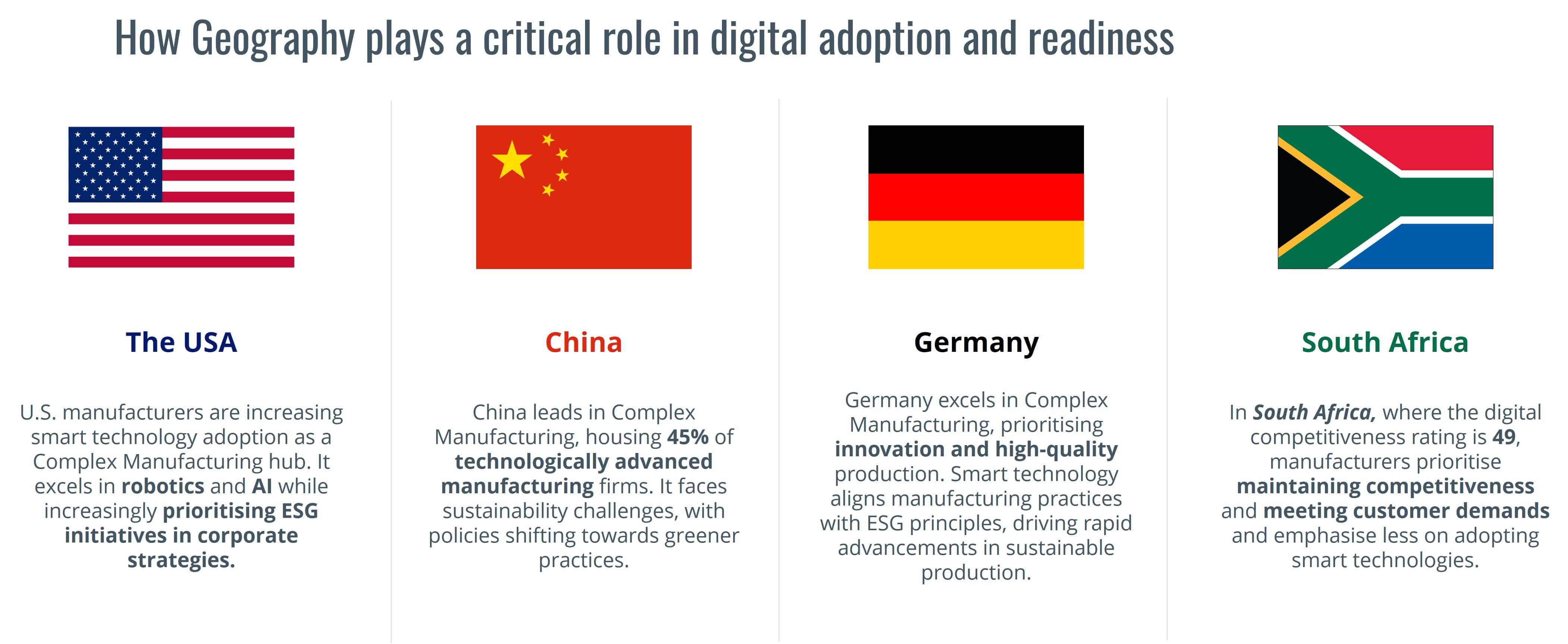

- Which country leads in technology adoption?

Technology adoption differs widely across the regions analyzed, driven by evolving industry demands, financial capacities, and access to advanced technologies.While the USA leads in digital readiness, it struggles with slow technology adoption, in small to mid-sized manufacturing. China leads in adoption with 45% of manufacturers adopting emerging technology.

Digital readiness and access to advanced technologies play a large role.

- How important is sustainability for complex manufacturers?

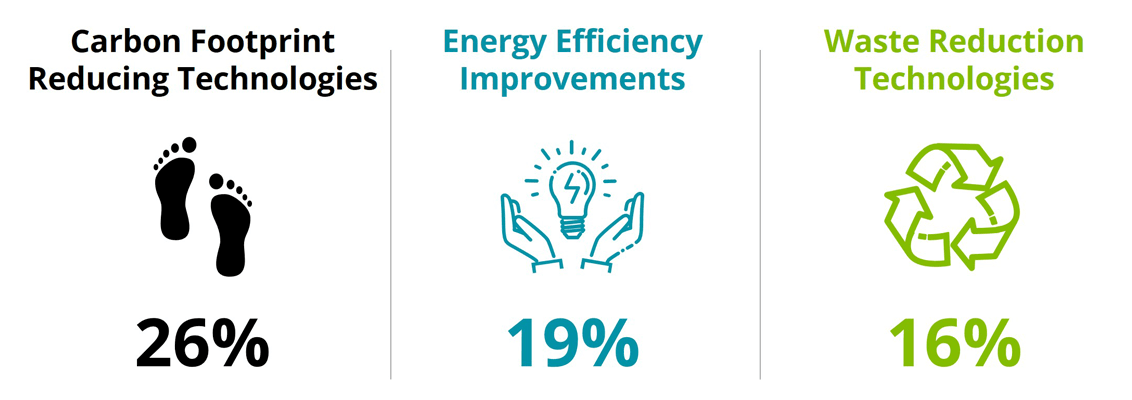

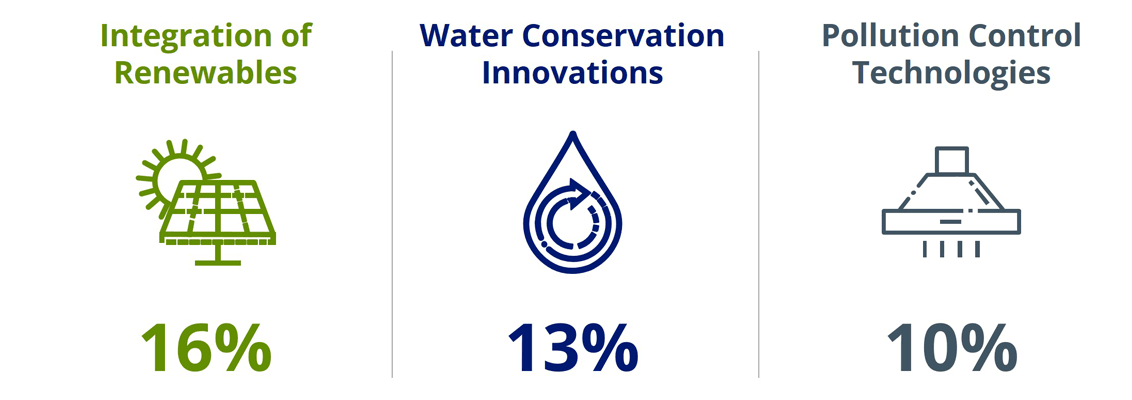

Almost 50% of the respondents in our survey mentioned investment in sustainable technologies, with North America and Europe leading in implementations.

Though still at an early stage, sustainability practices are expected to become a prime focus of manufacturers in the near future.In fact, using some of these emerging technologies not only makes operations efficient but also helps in reducing carbon emissions. Our report discusses how the application of additive manufacturing, digital twins, and IoT is helping manufacturers reduce waste.Technological advancements empowering complex manufacturers to become more sustainable

Additionally, you can explore what other manufacturers are saying about their sustainability practices in the full report.

- Which challenges are hindering manufacturers in advanced technology adoption?

The survey results highlight five top challenges. Not surprising, high upfront costs (25%) and resistance to change (22%) are major barriers for complex manufacturers.

However, many manufacturers are managing these challenges through better planning and executive support. It’s definitely easier said than done!